PSA offers a diverse and comprehensive portfolio of Robotic & Custom Automation, Drives, Controls and Safety Solutions, along with Standard Product offerings for the Consumer Packaged Goods, Healthcare, Medical Devices, and Light Manufacturing industries. Staffed with over 200+ years of combined experience in the Automation and Engineering Industry, PSA is your "One Stop Shop" Automation Solutions Provider!

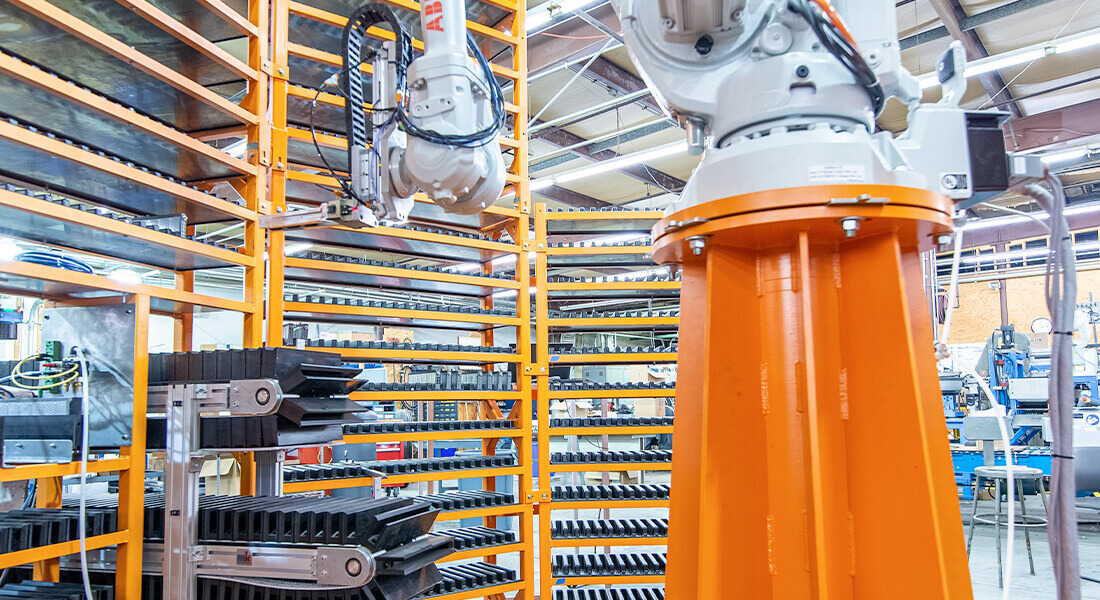

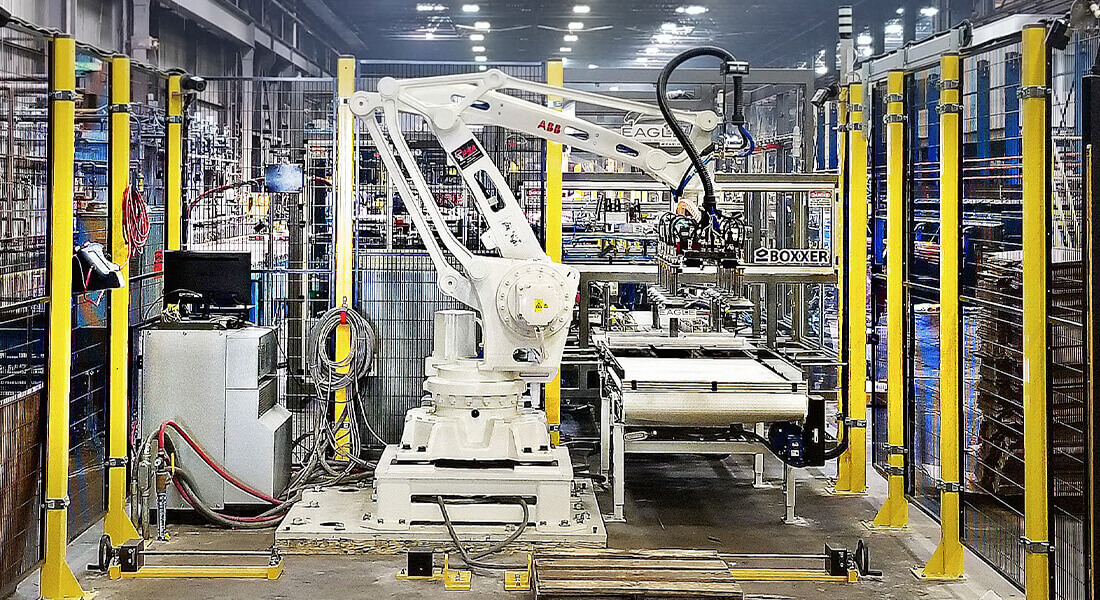

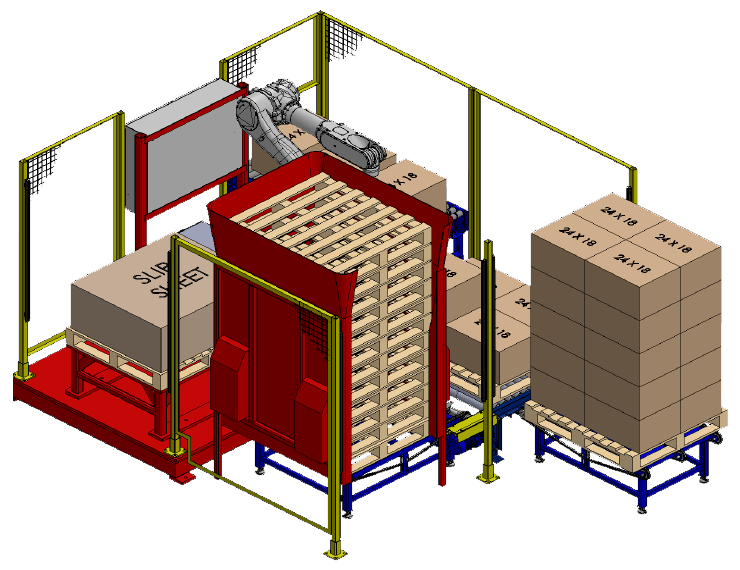

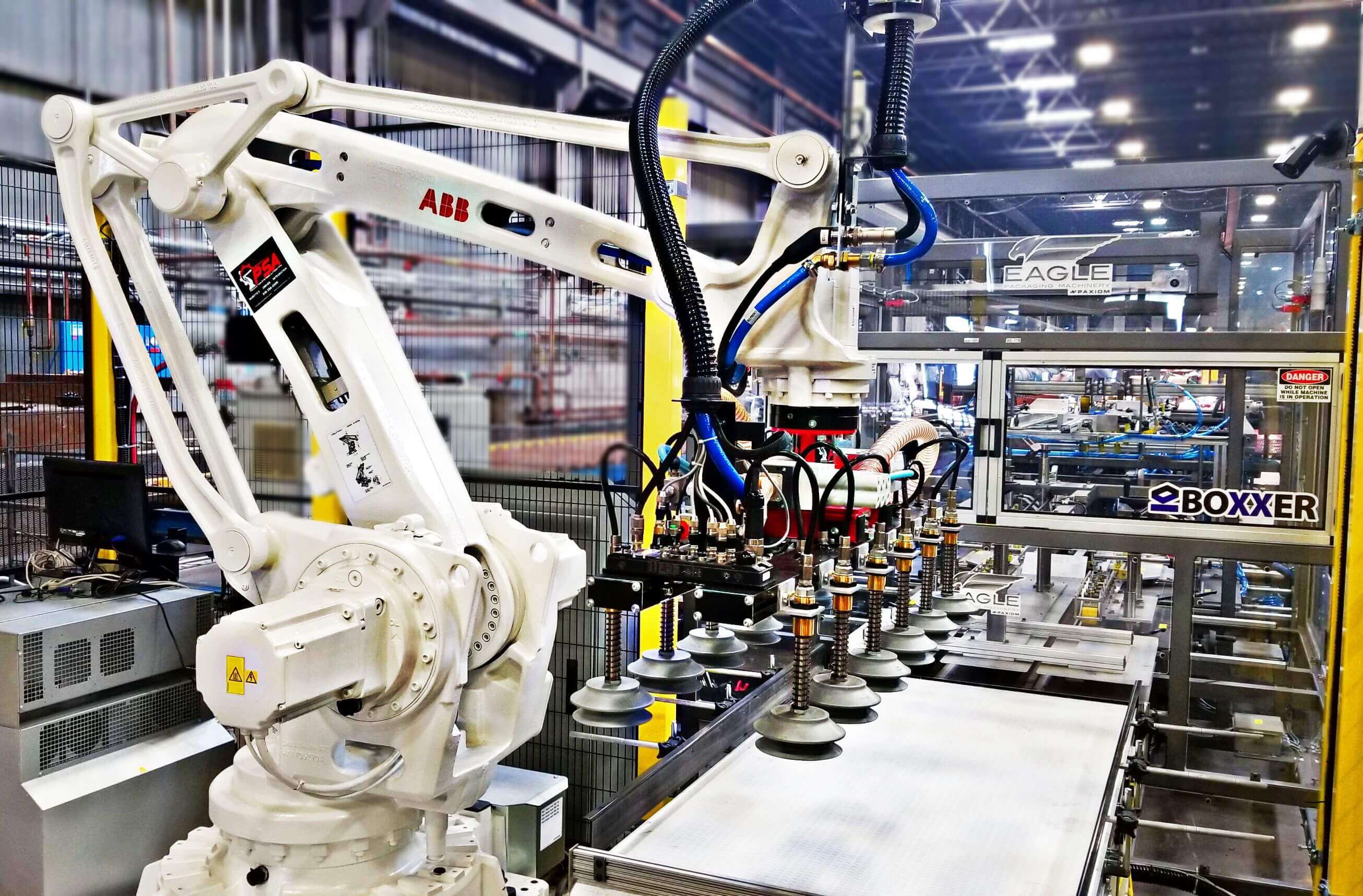

PSA Systems has the capability to program and integrate a wide variety of industrial and collaborative robots that can be customized to best fit your application requirements. Our core business is to source commercially available or custom designed components and integrate them together to provide a full turnkey robotic automation solution.

We are an experienced robotics systems integrator partnered with Kawasaki, Fanuc, ABB, and Yaskawa/Motoman.

Utilizing state of the art robot simulation tools, PSA Systems can check reach, payload and safety zone requirements in order to specify the best model robot to meet your application requirements.

Simply reach out to one of our sales and applications engineers to discuss your next automation project! Click here to email us.

PSA also integrates the following as part of the total robotic system package:

PSA's Sniper Cell is designed for high-speed, vision guided pick & place, case packing, carton loading, kitting and assembling applications. It is a pre-engineered, modular solution that allows for easy integration of high speed delta, scara and/or 6 axis robots; along with a wide variety of vision sensors and conveyors options.

The PSA Sniper Cell enhances packaging and assembly lines, making them more standardized, scalable and user friendly.

PSA is a complete Drives Systems Integrator. We are industry leaders in providing PLC's, AC/DC Variable Speed Drives, Motion Control and HMI's.

Reliable drive systems are key to a safe and efficient operation and can allow for increased production. PSA offers Drive Programming, Tuning and Optimization services for your existing equipment. We offer both turn-key sectionalized drive systems and single or multi-drive system upgrades. PSA has many years of experience programming, servicing and upgrading drive and motion control systems for paper, material handling and packaging equipment.

PSA provides Drive Systems Solutions for the following OEM's:

PSA can custom design a new controls or safety package for your equipment to allow implementation of the industry's latest PLC and safety systems and electrical controls technology. We are able to create custom operator interface HMI, control and operator panels for new or existing equipment. We can integrate PLC communication in order to provide drive, motion and safety process control. We also have engineers and technicians available to perform Total Machine Onsite Safety Validations and Safe Operator Access (SOA) evaluations.

Control Systems Experience:

PSA provides Turnkey Integrated Safety Solutions to guarantee proper fit and function. Prior to shipment, PSA performs a complete safety integration FAT of all safety keyed interlocks, switches and other safety devices and controls; thereby reducing installation and commissioning time at your facility.

Turnkey Safety Solutions Include:

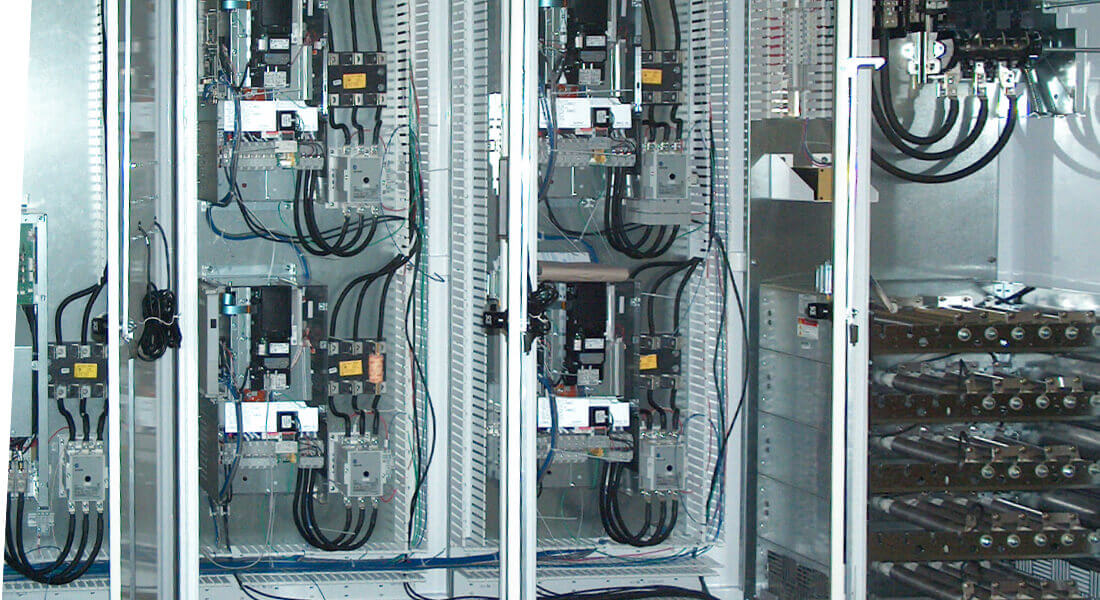

PSA takes great pride in our electrical control and drive panels. Our panel fabricators are skilled technicians who have the experience to ensure the panels we build will exceed our highest standards of functionality and appearance. We have terminal marking tag printers, can provide options for panel marking and are certified to build UL 508 electrical panels. No matter what size or function, you can be assured we will deliver the highest quality panels on time at a reasonable price.

PSA provides Standard Product Solutions for the Food and Beverage, Paper Converting and Healthcare Markets. Such equipment as Hot Fill Liquid Test Machines, CorePlug Solutions, Dunnage Sorters and Bed Bug Ovens are just a few of the standard solutions that PSA provides.

Hot Fill Machines are custom built for the PET Industry to accommodate bottle and temperature specifications, with capacity to fill up to 16 bottles at a time.

Each empty bottle is placed on a “one size fits all” plate that centers the bottles under the fill heads. The door is closed, and the fill head automatically lowers to fill the bottles. When the bottles are filled, the operator presses the RAISE button and the fill heads return to the top. Indicator lights tell the operator when to cap the bottles and when to remove them and place them in the Bottle Cooler.

Standard Hot Fill Features Include:

PSA's bed bug ovens have been purchased for use in many hospitals, health care and Veteran Affairs facilities across the United States that may be prone to bed bug infestation. The Bed Bug Oven is heated to a temperature of 130°F (54°C) to kill all bed bug life stages present. The oven plugs into a standard 220VAC outlet and can be fabricated to spec for any treatable space.

The Dunnage Sorting Machine is designed and built to sort PET Container Dunnage (Frames, Slip Sheets and Pallets)

Typical Repair Costs:

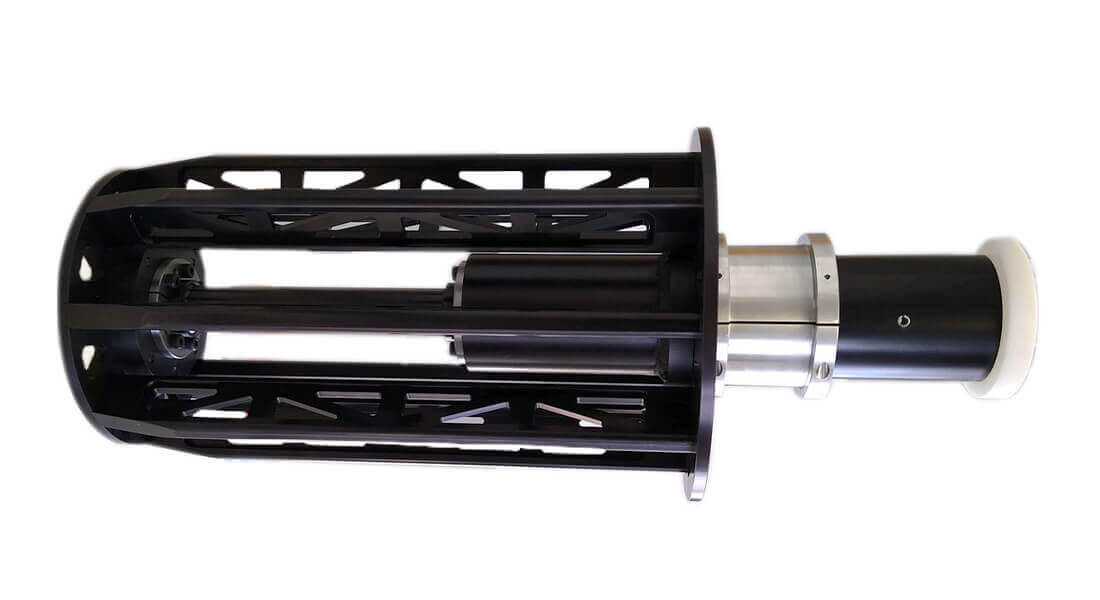

Today's Paper and Converting Mills continue to be challenged with maintaining their fleet of outdated and damaged core plugs. The result of poor quality or damaged core plugs can be catastrophic; leading to significant operator safety issues when handling large parent rolls. Moreover, there is a potential for downstream Parent Roll processing issues resultant from utilizing damaged/fractured core plugs.